Supervisors: Ed Pickering (University of Manchester).

Reduced-activation ferritic/martensitic (RAFM) steels, such as Eurofer 97, are primary candidate materials for blanket components in future fusion reactors. It is hoped that they will be able to withstand the high temperatures, high irradiation doses, and other material-degrading conditions found in fusion reactors. However, their ability to withstanding these extreme conditions will depend critically on their microstructural features, such as grain size and precipitate distribution. In turn, these features are directly impacted by the processing steps applied during manufacture, such as heat treatment (e.g., RAFM steels undergo an austenitisation, quench, and ageing). Processing steps must be optimised and carefully controlled to achieve the best microstructures and properties.

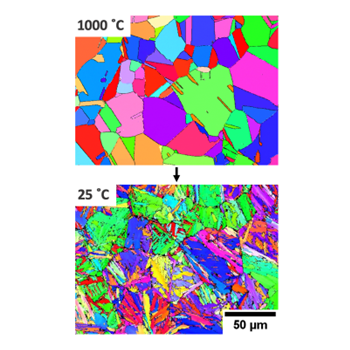

Recently, the University of Manchester has led the development of in-situ rapid high-temperature electron backscatter diffraction (EBSD) to observe phase transformation in alloys with high temporal and spatial resolution. This exciting technique has allowed researchers to observe changes in the microstructure in real time, providing information about the phase transformations occurring during processing, which before we only inferred from indirect observations. We have begun to uncover unexpected behaviours that could have wider implications for the processing of steels like RAFM steels. Figure 1 presents two images from an in-situ experiment in which a steel was austenitised (heated to high temperature) and then cooled to form martensite.

This PhD project will use advanced in-situ EBSD, alongside other routine characterisation techniques, to elucidate microstructural development during the processing of novel RAFM steels developed at UKAEA. It will investigate links between microstructural features and processing conditions, and make recommendations regarding optimal heat treatment practices for RAFM steel manufacture.

The successful candidate will have a good undergraduate degree in a relevant subject, e.g., materials science, physics or engineering. Previous specialisation in metallurgy or fusion energy is not required as students will gain a broad understanding through the taught component of the CDT programme and through their preliminary research. This project will provide the opportunity to develop transferable skills and knowledge of industrial processes, metallurgy, electron microscopy, and other analysis techniques, which should ensure the candidate is prepared for a wide range of possible career paths after graduation. Generic transferrable skills associated with programming, data manipulation and data interpretation will be gained.

[1]. M. Taylor, A.D. Smith, J.M. Donoghue, T.L. Burnett and E.J. Pickering, In-situ heating-stage EBSD validation of algorithms for prior-austenite grain reconstruction in steel, Scripta Materialia 242 (2024) 115924.

The project will be mainly based in Manchester, but there is the opportunity for travel to conferences and collaborations with other groups.

This project is offered by University of Manchester. For further information please contact: Ed Pickering (ed.pickering@manchester.ac.uk)

This project may be compatible with part time study, please contact the project supervisors if you are interested in exploring this.